Sew-motor (Suzhou) Co., Ltd. inspected our company and gave a high degree of recognition

2022-12-8 Browse: 2147 Author:

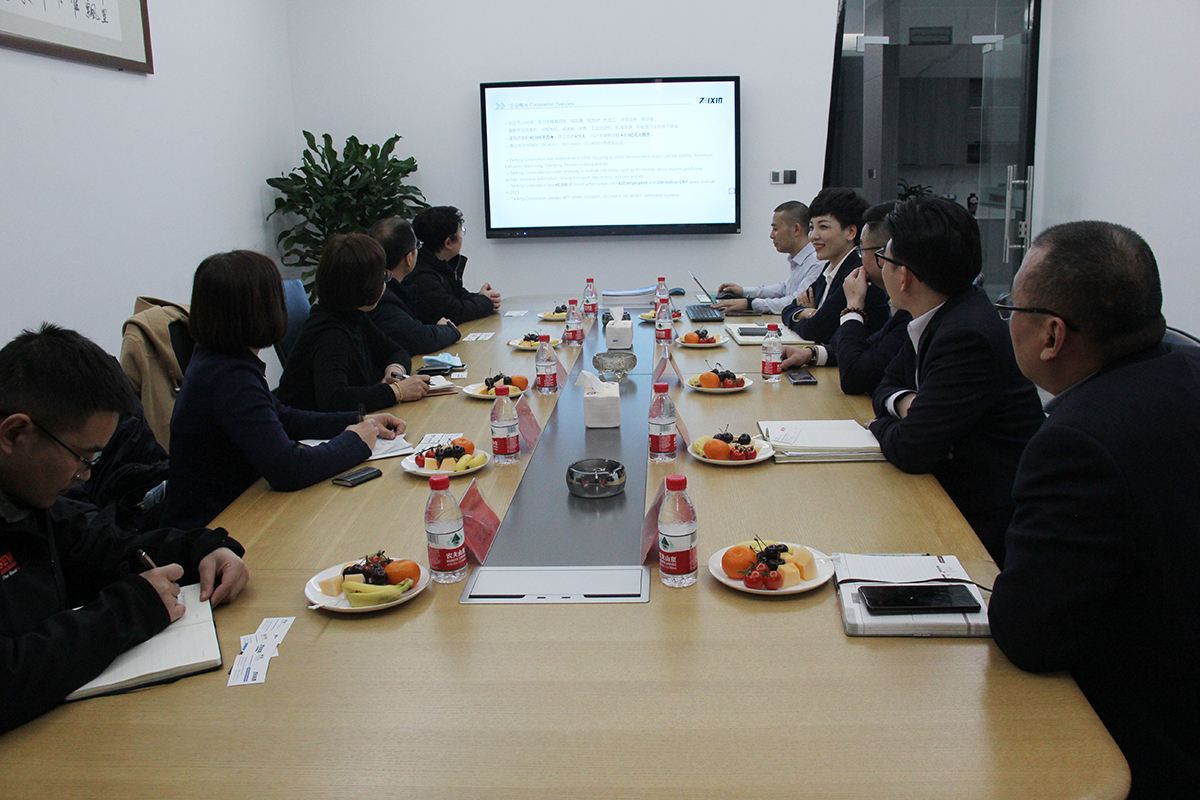

On the afternoon of December 6, Pan Yun, senior manager of SEW-Electric (Suzhou) Co., LTD., senior manager of the Purchasing Department, Zhang Yunzhe, senior manager of the Technical department, director of the Purchasing department, director of the quality Department, process engineer and other five people arrived at our company for a one-day investigation. Zhang Lingbin, general manager of our company, led the manager of Marketing Department, the manager of technology development Department, the manager of quality Control Department and the deputy manager of Marketing Department to warmly receive.

First of all, the deputy marketing manager to introduce the company PPT to the guests, including the companys current situation, development process, corporate culture, production process (order), production scale, hardware strength, management system, future strategy, etc. Then, Pan Yun, Zhang Yunzhe two managers respectively on production, quality, technology, process, internal control and other aspects of the professional inquiry. The companys marketing manager, quality control manager and technical development manager respectively answered the inquiries of each profession and added: After more than 20 years of development, Taiching Company has basically realized large-scale, automation and data-oriented management. We have been adhering to the principle of "customer service as the center", which is not only reflected in the product delivery and quality, but also reflected in our integrity and constructive cooperation thinking.

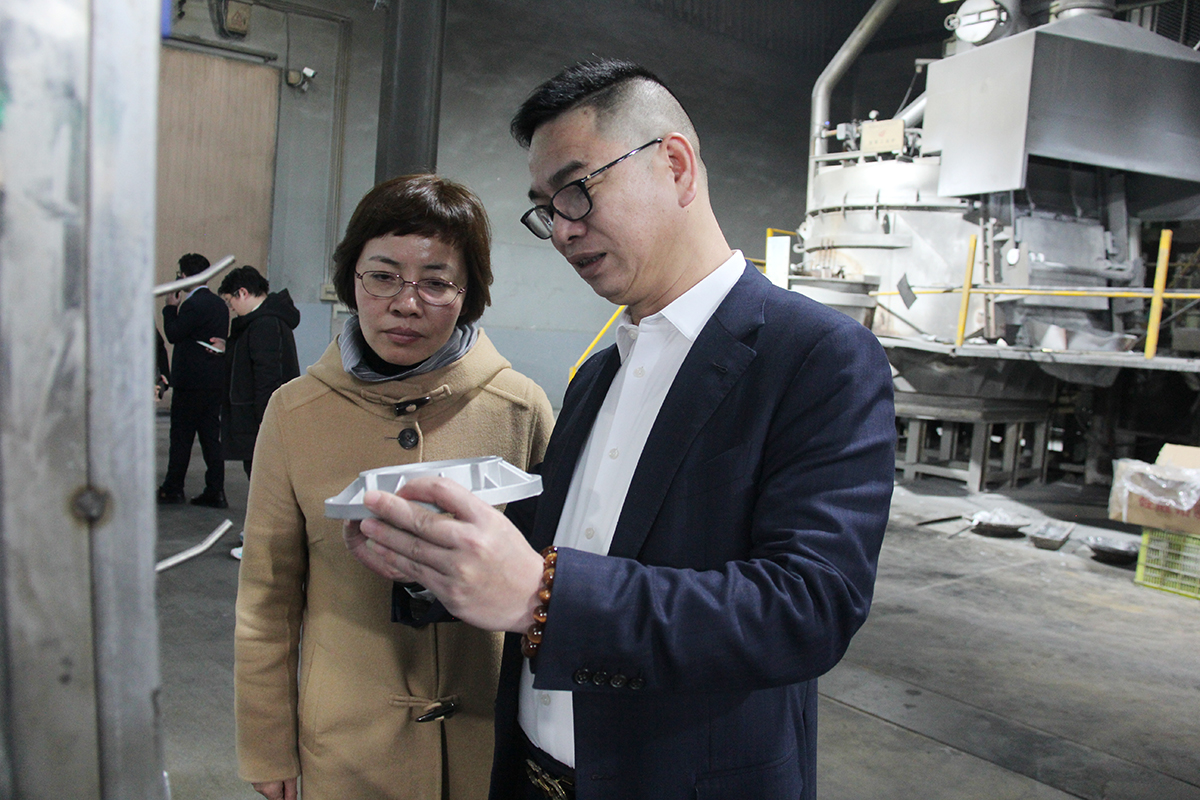

Subsequently, under the leadership of General Manager Zhang, the customer group visited the mold workshop, die casting workshop, surface treatment workshop, spray workshop, constant temperature workshop and the full inspection line of cleaning. During the visit, both sides also had extensive and in-depth exchanges on various management and technical issues in the actual production process, and were full of praise for our companys standardized site management and the vitality of the site personnel. A group of people then came to the negotiation room for summary communication. Guests said: As the SEW Group motor manufacturing center in the Asia-Pacific region, Suzhou company has been relying on the German quality standards, international first-class production equipment, advanced technology and service concept, to win the unanimous recognition and praise of the majority of customers, the overall development of healthy and orderly, sustained growth. Therefore, when we investigate and develop suppliers, we pay special attention to their production and management strength as well as the sustainability of the enterprise. We are deeply impressed by the good image you have shown today, especially your hardware strength and internal management. We also hope to have deeper communication and discussion in the following time, until we can work together. Finally, Mr. Zhang expressed his thanks to the guests for their high recognition and said: SEW as a global motor, reducer, frequency conversion electronic equipment multinational enterprises, the technical level and market share are in the worlds leading position, there are many areas and modules worth us to learn, hope that in the future SEW and Taixing can have more opportunities to exchange, also hope to be able to achieve deep cooperation with SEW, long-term development, Together, we are committed to providing the most valuable products and services for end customers and creating a century-old enterprise. At the same time, we also welcome SEW experts to Taixing to walk and talk.

[Friendly group photo]

About Tai Hing

About Tai HingZhejiang Taixing Electromechanical Technology Co., LTD., founded in 2000, is located in Taizhou, a coastal city with beautiful scenery and convenient transportation. Over the past 20 years, the company has been focusing on the research and development, production and sales of aluminum die-casting, aluminum tensile motor housing and stamping parts. The products are widely used in new energy vehicles, industrial automation, motor, reducer, water pump, fan, cleaning machine, high-speed rail, military equipment and other fields.

With the core mission of "transferring scientific and technological power to help the world industry", the company always adheres to the development idea of "technological innovation is the core competitiveness" and pays attention to the design, development and upgrading of products. After 20 years of precipitation and hard work, the company has formed a strong product design, mold development and product delivery capabilities. It has embarked on a new road of development featuring high technological content, low resource consumption, large scale equipment and less environmental pollution. At present, we have 42 sets of die casting machines of various tonnage such as Ezhimi and Lixin, and more than 400 sets of various high, fine and advanced machining equipment, mold manufacturing equipment and surface treatment equipment such as Mazak, Brothers, Lichi and Taigroup. We also introduce Zeiss/Wenze CMM, spectrometer, imager, profile and other testing equipment, which provides reliable strength guarantee for the delivery time and quality of products. At present, the company has more than 400 employees, including more than 80 technical and managerial personnel at all levels, and has achieved an annual output of more than 13,000 tons of aluminum alloy die casting and tensile parts, and an annual output of more than 400 sets of aluminum die casting moulds.

Return

Return