Preventive measures and new removal methods of burr in aluminum die castings

2021-9-12 Browse: 2712 Author: Congxu.Ran

Key words: Die Casting; skin needling; Thermal deburring

In die-casting production, there are metal flakes on the parting surface and core matching edge of die-casting parts, which are called burrs. Burr is the most common problem of die castings. It will not only affect the size and assembly accuracy of products, but also seriously affect the appearance of products. The amount of burrs is one of the important indexes to measure the quality of die castings. The more burrs, the lower the quality standard.

In the actual industrial production, there is no fundamental way to completely solve the problem of deburring die castings. In a sense, the emergence of burr still has the objective existence and inevitability of the industry. The main causes are that the moving and fixed dies of the die-casting machine are not matched well, various injection conditions of the die-casting machine are not adjusted to the best state, and the die structure such as sprue and exhaust design are unreasonable. Moreover, even if there are no problems with the above factors, the products produced in the initial stage have no burrs, but over time, the products produced by the mold will also have burrs due to dirt, wear and other reasons in the mold. The resulting repeated mold washing and repair will also affect the production efficiency and the service life of the mold. It can be seen that the analysis of die casting burr and the research of burr removal method have important practical value. By analyzing the causes of burr of die-casting parts of a photoelectric product base, this paper puts forward a reasonable and effective burr prevention and removal scheme.

1. Generation and cause analysis of die casting burr

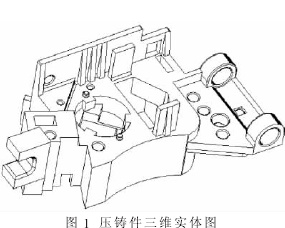

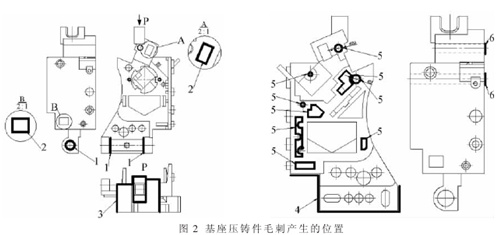

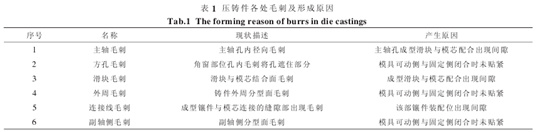

The three-dimensional solid of aluminum die casting analyzed is shown in Figure 1. The lens, bearing, coil, etc. shall be installed on it. There are nearly 50 precision parts in total. The minimum position tolerance of X, y and Z axial main and auxiliary shafts and holes is 0.005 mm, and the installation angle deviation of each lens is less than 0.5 °. It belongs to precision die casting, and the burr control is very strict. Through the statistical analysis of the bad engineering information of the product in recent years, we find that burr is one of the main factors affecting its quality. The burr parts of the product are shown in Figure 2. 1 - spindle burr; 2 - square hole burr; 3 - slider burr; 4 - peripheral burr; 5 - burr of connecting wire; 6 - secondary shaft side burr; 7 - thimble burr. Next, we will make a specific analysis on the burrs and causes of the above parts, as shown in Table 1.

(1) Avoid burrs

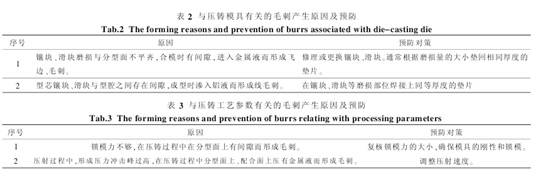

In the production process, there are many factors causing burr, mainly including the stability of die casting machine performance, the selection of die casting process parameters, alloy composition and melting process, the use of release agent, the rationality of die structure and manufacturing quality. From the engineering practice, the performance and die structure of the die casting machine are rarely changed. Therefore, how to adjust the die casting process parameters and some simple repair of the die, so as to improve the product quality is particularly important. Combined with practical experience, this paper summarizes the possible causes and Preventive Countermeasures of burr in die-casting die and process parameters, as shown in Table 2 and table 3.

For another example, 6 burrs (secondary shaft side burrs): there are line burrs on the end surface of the hole 12 here, and the thickness of the line burrs is up to 0.02 mm, which is difficult to remove in subsequent processes. Check the mold condition because Φ There is mutual movement between the 12 mm hole core pulling sliding block and the cavity insert. There is a gap due to wear after a long production time. During die-casting molding, aluminum liquid infiltrates into the sliding block to produce line burrs. A 0.02 mm gasket is welded on the worn part of the sliding block, and the burrs disappear.

(2) Traditional deburring method

The traditional deburring method of die castings is to manually remove the burrs one by one by using manual tools such as files and cutting tools. This method consumes a long man hour and has low production efficiency. Moreover, like the precision die castings in this paper, it has high precision requirements, so manual deburring can not meet the requirements of use. In addition, the burr around the casting can also be removed when removing the riser with the stamping die, but this method can not remove the burr at the internal structure and details.

(3) New method of deburring

For the die castings in this paper, a new technology is used to remove burrs, that is, thermal deburring. The working principle of thermal deburring is as follows: place the parts to be deburred in a closed container, and then charge a certain amount of hydrogen (or methane) and oxygen. After being ignited by the spark plug, the mixed gas reacts in an instant to release a large amount of heat, so that the burr (flash) can heat and spontaneously ignite under the action of high temperature (about 3000 ℃), high pressure (20 times the inflation pressure) and high speed (8 times the sound speed), And achieve the purpose of deburring (flash).

Compared with the part matrix, the burr has a large surface area and relatively small volume, so it can absorb more heat. Moreover, due to the good penetration of gas, it has a good removal effect for some parts that are difficult to remove by hand. The burr root is generally thin and thin, which can well inhibit the heat transfer to the interior of the part. Moreover, the reaction time is very short, so only small burrs can be removed by combustion. Due to the heat generated on the main part.

The body will not have any impact, so it generally will not change the basic properties of parts, and the deburring efficiency is very high and the process performance is stable.

3. Conclusion

By analyzing the causes and removal methods of burr in die casting parts of photoelectric product base, two feasible schemes are put forward: one is to avoid burr by controlling die casting process parameters and adjusting die structure; The second is to use a new technology - thermal deburring method to remove burrs. This method has the characteristics of wide application range, simple fixture, low cost, fast processing capacity and short cycle time.

Return

Return