A common method of deburring aluminum die casting

2020-12-29 Browse: 2936 Author:

The burr of aluminum alloy is inevitable. There are many ways to deal with burr at present. In the process of die casting, burr is inevitable due to the factors such as pressure impact and lack of clamping force. In recent years, with the increasing quality requirements of die casting, the burr requirements are also more stringent, and at the same time, deburr methods emerge in an endless number. The deburring process is the most troublesome. The following are the advantages and disadvantages of various deburring methods for die-casting parts, so that you can have a better understanding of various deburring methods and choose the appropriate deburring method according to your own needs.

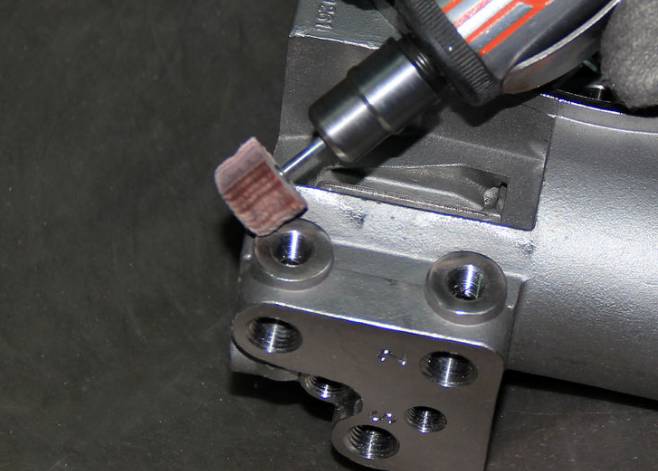

1. Manual deburring

This is the most traditional and common die - casting tool used in die - casting plants. It uses file (both manual and pneumatic), sandpaper, tape grinder, grinding etc as auxiliary tools.

Disadvantages: high labor cost, low efficiency, and difficult to remove complex cross holes.

Applicable objects: low technical requirements for workers, suitable for aluminum alloy die casting with small burr and simple product structure.

2. Deburring the die

Deburring is carried out by making die and press.

Disadvantages: a certain amount of die (coarse die + fine die) production costs, may also need to make plastic die.

Suitable for aluminum alloy die casting with simple parting surface, with better efficiency and deburring effect than manual work.

3. Grind and deburr

This kind of deburring includes vibration, sand blasting, roller and so on.

Disadvantages: There is a problem that the removal is not very clean, and the residual burrs may need subsequent manual treatment or other ways of deburring.

Suitable for large batch of small aluminum alloy die casting parts.

4. Freeze to deburr

The burrs are quickly embrittlement by cooling, and then the burrs are removed by spraying the projectile. The equipment price is about two or three hundred thousand;

Suitable for die casting of aluminum alloy with small burr wall thickness and volume.

5. Heat explosion deburring

Also called heat deburring, explosion deburring. By passing some natural gas into an equipment furnace, and then through the action of some media and conditions, the gas burst in an instant, using the energy generated by the explosion to dissolve and remove burrs.

Disadvantages: expensive equipment (millions of price), high technical requirements, low efficiency, side effects (rust, deformation);

Applicable objects: mainly used in some high-precision parts, such as automotive aerospace and other precision parts.

6, carving machine deburring

The equipment is not very expensive (tens of thousands).

Applicable object: suitable for simple spatial structure, simple and regular deburring position.

7. Chemical deburring

Electrochemical reaction principle, the metal materials made of parts automatically, selectively to complete the deburring operation.

Applicable object: it is suitable for the internal burr which is difficult to remove, and it is suitable for the pump body, valve body and other products with fine burr (thickness less than 7 silk).

8. Electrolytic deburring

An electrochemical machining method for removing the burrs of aluminum alloy die casting by electrolysis. Electrolytic deburring is suitable for removing burring of concealed cross holes or complex parts in aluminum alloy die casting with high production efficiency and the deburring time generally takes only a few seconds to dozens of seconds.

Disadvantages: the electrolyte has a certain corrosion, the parts burr nearby is also affected by electrolysis, the surface will lose the original luster, or even affect the dimensional accuracy, aluminum alloy die casting after deburring should be cleaned and rust treatment.

Applicable object: suitable for gear, connecting rod, valve body and crankshaft oil orifice deburring, as well as rounded corners.

9, high pressure water jet deburring

With water as the medium, the instant impact force can be used to remove the burr and flash produced after processing, and the purpose of cleaning can be achieved at the same time.

Cons: Expensive equipment

Applicable object: mainly used for automobile heart parts and hydraulic control system of construction machinery.

10. Ultrasonic deburring

Ultrasonic wave produces instantaneous high pressure to remove burrs.

Applicable objects: mainly for some microscopic burrs. Generally, if burrs need to be observed by microscope, ultrasonic method can be used to remove them.

11, abrasive flow to burr

Conventional vibration grinding, which is difficult to cope with burrs of holes, is a typical abrasive flow machining process (bidirectional flow) in which the abrasive is pushed back and forth through the passage formed by the workpiece and the fixture through two perpendicular opposite abrasive cylinders. Abrasive entering and flowing through any restricted area produces a grinding effect. The extrusion pressure is controlled at 7-200bar(100-3000 psi), suitable for different travel and different cycles.

Applicable object: Can handle 0.35mm micro burr, no secondary burr, fluid characteristics can handle complex location burr.

12. Magnetic deburring

Magnetic abrasive machining is under the effect of magnetic field, the filling in the magnetic abrasive in the magnetic field is along the lines of magnetic force lines up the direction of the adsorption "abrasive brush" is formed on the magnetic poles, the workpiece surface and generate a certain amount of pressure, magnetic pole in the abrasive brush rotates at the same time, keep a certain gap, moving along the workpiece surface so as to realize the workpiece surface finishing processing.

Features: low cost, wide processing range, easy operation

Process elements: grinding stone, magnetic field strength, workpiece speed, etc

13. Robot polishing unit

The principle is similar to manual deburring, but the power is turned into a robot. With the support of programming technology and force control technology, flexible polishing (pressure and speed change) is realized, and the advantages of robot deburring are highlighted.

Return

Return